Southwest Wire Rope Products

Professional Rigging Made for Professionals

- Wire Rope

- Wire Rope Fittings

- Wire Rope Slings

- Chains

- Synthetic Web and Round Slings

- Straightpoint Load Monitoring Products

- Wire Rope

- Wire Rope Slings

- Chains

- Synthetic Web Slings

- Synthetic Round Slings

- Synthetic Rope

- Hardware

- General Purpose

- Crane

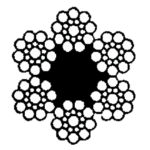

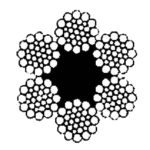

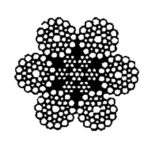

- 6 x 19

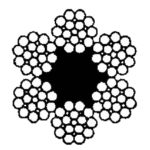

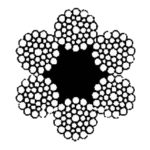

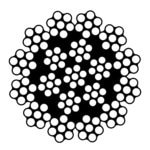

- 6 x 36

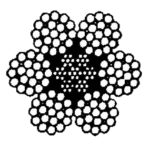

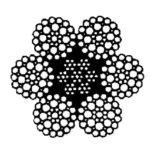

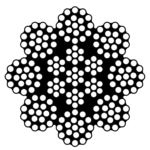

- 6 x 36 – Large Diameter

NOMINAL STRENGTHS OF WIRE ROPE

6 x 19 Classification/Bright (Uncoated),

or Drawn-Galvanized, Fiber Core, EIPS

|

Nom. Diam. |

Nominal Strength |

Approx. Mass |

|---|---|---|

|

Inches |

EIPS |

Lb/Ft |

Tons |

||

|

1/4 |

3.02 |

0.11 |

|

5/16 |

4.69 |

0.16 |

|

3/8 |

6.72 |

0.24 |

|

7/16 |

9.10 |

0.32 |

|

1/2 |

11.8 |

0.42 |

|

9/16 |

14.9 |

0.53 |

|

5/8 |

18.3 |

0.66 |

|

3/4 |

26.2 |

0.95 |

|

7/8 |

34.4 |

1.29 |

|

1 |

46.0 |

1.68 |

|

1 1/8 |

57.8 |

2.13 |

|

1 1/4 |

71.1 |

2.63 |

|

1 3/8 |

85.5 |

3.18 |

|

1 1/2 |

101 |

3.78 |

|

1 5/8 |

118 |

4.44 |

|

1 3/4 |

137 |

5.15 |

|

1 7/8 |

156 |

5.91 |

|

2 |

176 |

6.72 |

|

2 1/8 |

197 |

7.59 |

|

2 1/4 |

220 |

8.51 |

6 x 19 Classification/Bright (Uncoated),

or Drawn-Galvanized, IWRC, EIPS

|

Nom. Diam. |

Nominal Strength |

Approx. Mass |

|---|---|---|

|

Inches |

EIPS |

Lb/Ft |

| Tons | ||

|

1/4 |

3.40 |

0.12 |

|

5/16 |

5.27 |

0.18 |

|

3/8 |

7.55 |

0.26 |

|

7/16 |

10.2 |

0.35 |

|

1/2 |

13.3 |

0.46 |

|

9/16 |

16.8 |

0.59 |

|

5/8 |

20.6 |

0.72 |

|

3/4 |

29.4 |

1.04 |

|

7/8 |

39.8 |

1.42 |

|

1 |

51.7 |

1.85 |

|

1 1/8 |

65.0 |

2.34 |

|

1 1/4 |

79.9 |

2.89 |

|

1 3/8 |

96.0 |

3.50 |

|

1 1/2 |

114 |

4.16 |

|

1 5/8 |

132 |

4.88 |

|

1 3/4 |

153 |

5.67 |

|

1 7/8 |

174 |

6.50 |

|

2 |

198 |

7.39 |

|

2 1/8 |

221 |

8.35 |

|

2 1/4 |

247 |

9.36 |

|

2 3/8 |

274 |

10.4 |

|

2 1/2 |

302 |

11.6 |

|

2 5/8 |

331 |

12.8 |

|

2 3/4 |

361 |

14.0 |

(Meets or exceeds federal specification RR-W-41O [latest revision].)

NOMINAL STRENGTHS OF WIRE ROPE

6 x 36 Classification/Bright (Uncoated),

or Drawn-Galvanized, Fiber Core, EIPS

|

Nom. Diam. |

Nominal Strength |

Approx. Mass |

|---|---|---|

|

Inches |

EIPS |

Lb/Ft |

|

Tons |

||

|

1/4 |

3.02 |

0.11 |

|

5/16 |

4.69 |

0.16 |

|

3/8 |

6.72 |

0.24 |

|

7/16 |

9.10 |

0.32 |

|

1/2 |

11.8 |

0.42 |

|

9/16 |

14.9 |

0.53 |

|

5/8 |

18.3 |

0.66 |

|

3/4 |

26.2 |

0.95 |

|

7/8 |

34.4 |

1.29 |

|

1 |

46.0 |

1.68 |

|

1 1/8 |

57.8 |

2.13 |

|

1 1/4 |

71.1 |

2.63 |

|

1 3/8 |

85.5 |

3.18 |

|

1 1/2 |

101 |

3.78 |

|

1 5/8 |

118 |

4.44 |

|

1 3/4 |

137 |

5.15 |

|

1 7/8 |

156 |

5.91 |

|

2 |

176 |

6.72 |

|

2 1/8 |

197 |

7.59 |

|

2 1/4 |

220 |

8.51 |

6 x 36 Classification/Bright (Uncoated),

or Drawn-Galvanized, IWRC, EIPS

|

Nom. Diam. |

Nominal Strength |

Approx. Mass |

|---|---|---|

|

Inches |

EIPS |

Lb/Ft |

|

Tons |

||

|

1/4 |

3.40 |

0.12 |

|

5/16 |

5.27 |

0.18 |

|

3/8 |

7.55 |

0.26 |

|

7/16 |

10.2 |

0.35 |

|

1/2 |

13.3 |

0.46 |

|

9/16 |

16.8 |

0.59 |

|

5/8 |

20.6 |

0.72 |

|

3/4 |

29.4 |

1.04 |

|

7/8 |

39.8 |

1.42 |

|

1 |

51.7 |

1.85 |

|

1 1/8 |

65.0 |

2.34 |

|

1 1/4 |

79.9 |

2.89 |

|

1 3/8 |

96.0 |

3.50 |

|

1 1/2 |

114 |

4.16 |

|

1 5/8 |

132 |

4.88 |

|

1 3/4 |

153 |

5.67 |

|

1 7/8 |

174 |

6.50 |

|

2 |

198 |

7.39 |

|

2 1/8 |

221 |

8.35 |

|

2 1/4 |

247 |

9.36 |

|

2 3/8 |

274 |

10.4 |

|

2 1/2 |

302 |

11.6 |

|

2 5/8 |

331 |

12.8 |

|

2 3/4 |

361 |

14.0 |

|

2 7/8 |

392 |

15.3 |

|

3 |

425 |

16.6 |

|

3 1/8 |

458 |

18.0 |

|

3 1/4 |

492 |

19.5 |

|

3 3/8 |

529 |

21.0 |

|

3 1/2 |

564 |

22.7 |

|

3 5/8 |

602 |

24.3 |

|

3 3/4 |

641 |

26.0 |

(Meets or exceeds federal specification RR-W-41O [latest revision].)

6 x 36 Large Diameter

LARGE DIAMETER, HIGH STRENGTH

Specifications per API 9A

EEEIPS & Higher Grades are available on special order.

6 x 36 Classification Wire Rope Bright (Uncoated)

or Drawn-Galvanized Wire, Independent Wire Rope Core (IWRC)

|

Nominal |

Diameter |

Approximate |

Minimum |

||||

|---|---|---|---|---|---|---|---|

|

mm |

(in) |

min. mm |

max. mm |

kg/100 m |

(lb/ft) |

kN |

(short tons) |

|

63.5 |

(2 1/2) |

63.5 |

66.7 |

1,730 |

(11.6) |

2,950 |

(332) |

|

66.7 |

(2 5/8) |

66.7 |

70.0 |

1,910 |

(12.8) |

3,240 |

(364) |

|

69.9 |

(2 3/4) |

69.9 |

73.4 |

2,080 |

(14.0) |

3,530 |

(397) |

|

73.0 |

(2 7/8) |

73.0 |

76.7 |

2,280 |

(15.3) |

3,840 |

(432) |

|

76.2 |

(3) |

76.2 |

80.0 |

2,470 |

(16.6) |

4,160 |

(468) |

|

79.4 |

(3 1/8) |

79.4 |

83.4 |

2,680 |

(18.0) |

4,490 |

(505) |

|

82.6 |

(3 1/4) |

82.6 |

86.7 |

2,900 |

(19.5) |

4,830 |

(543) |

|

85.7 |

(3 3/8) |

85.7 |

90.0 |

3,130 |

(21.0) |

5,180 |

(582) |

|

88.9 |

(3 1/2) |

88.9 |

93.3 |

3,380 |

(22.7) |

5,520 |

(621) |

|

95.3 |

(3 3/4) |

95.3 |

100 |

3,870 |

(26.0) |

6,270 |

(705) |

|

102 |

(4) |

102 |

107 |

4,400 |

(44.0) |

6,340 |

(713) |

|

108 |

(4 1/4) |

108 |

113 |

4,960 |

(49.6) |

7,110 |

(799) |

|

114 |

(4 1/2) |

114 |

120 |

5,570 |

(55.7) |

7,900 |

(888) |

|

121 |

(4 3/4) |

121 |

127 |

6,200 |

(62.1) |

8,730 |

(981) |

|

127 |

(5) |

127 |

133 |

6,870 |

(68.8) |

9,590 |

(1,078) |

|

133 |

(5 1/4) |

133 |

140 |

7,410 |

(49.8) |

9,960 |

(1,120) |

|

140 |

(5 1/2) |

140 |

147 |

8,110 |

(54.5) |

10,800 |

(1,219) |

|

146 |

(5 3/4) |

146 |

153 |

8,870 |

(59.6) |

11,700 |

(1,320) |

|

152 |

(6) |

152 |

160 |

9,680 |

(65.0) |

12,700 |

(1,426) |

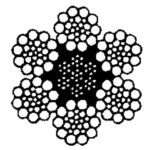

- Maxipact

- Rotation Resistant

- Compacted

Maxipact Overview

Oliveira NR Maxipact PPI

Properties

- Swivel

- Compacted

- Lubricated

- Tolerance

Oliveira NR Maxipact PPI

Properties

- Swivel

- Compacted

- Lubricated

- Tolerance

- PPI

Applications

All cranes and performant lifting devices where non-rotating and high MBL ropes are required.

Recommended for offshore, deck cranes, and marine environment.

- Temperature range of use: -50°C to +100°C

- Temperature range of use for option PPI: -50°C to +80°C

- Option PPI – only available for diameter ≥ 13mm

- Please add 1.0% on the weight for ropes with PPI

- Available in ordinary lay and Lang’s lay

- Available in right hand and left hand

|

RCN |

Diameter Range |

Construction |

Num. of |

Num. of wires |

Num. of |

Average fill factor |

Average spin factor |

|---|---|---|---|---|---|---|---|

|

23-3 |

12,70 - 52 |

37xK7 |

18 |

259 |

126 |

0,716 |

0.85 (1960*) |

|

30 |

54 - 64 |

37xK19 |

18 |

710 |

342 |

0,726 |

0.83 (1960*) |

|

>31 |

66 - 70 |

37xK26 |

18 |

1092 |

468 |

0,714 |

0.81 (1960*) |

Rotation Resistant Types

19 x 7 Classification/Bright (Uncoated)

or Drawn-Galvanized Wire Strand Core

|

Nominal Diam. |

Nominal Strength |

Approx. Mass |

|---|---|---|

|

1/4 |

2.77 |

0.113 |

|

1/16 |

4.30 |

0.175 |

|

3/8 |

6.15 |

0.25 |

|

7/16 |

8.33 |

0.35 |

|

1/2 |

10.80 |

0.45 |

|

9/16 |

13.60 |

0.58 |

|

5/8 |

16.80 |

0.71 |

|

3/4 |

24.00 |

1.02 |

|

7/8 |

32.50 |

1.39 |

|

1 |

42.20 |

1.82 |

|

1 1/8 |

53.10 |

2.30 |

|

1 1/4 |

65.10 |

2.84 |

8 x 19 Classification/Bright (Uncoated),

or Drawn-Galvanized, IWRC (EIPS)

|

Nominal Diam. |

Nominal Strength |

Approx. Mass |

|---|---|---|

|

1/2 |

11.6 |

.47 |

|

9/16 |

14.7 |

.60 |

|

5/8 |

18.1 |

.73 |

|

3/4 |

25.9 |

1.06 |

|

7/8 |

35.0 |

1.44 |

|

1 |

45.5 |

1.88 |

Meets or exceeds applicable APl-9A and federal specification RR-W-410 (latest revision).

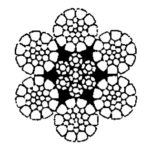

Compacted Strand

Mining, industrial, construction, logging, and oilfield applications.

Stability, strength, fatigue resistance, and abrasion resistance.

All popular sizes.

Longer service life.

Extra value means different things in different applications.

In applications where increased strength, stability, and abrasion resistance are beneficial. 6-strand compacted ropes are a natural and can result in longer service life. From boom hoist ropes and drag ropes in mining applications, to sawmill carriage ropes and mainline ropes in logging, their versatility and extra value make a difference.

As single-part hoist lines and wherever spooling problems, drum crushing, bird caging, block twisting and fast line speeds are likely to be encountered.

At the design and specification stage, ideal when machinery space and weight savings are important.

Greater fatigue resistance cuts rope expense in applications where fatigue is the primary cause for removal.

Ideally suited to rugged applications.

This rotation resistant, higher strength rope provides extra value in both original equipment designs and replacement applications. 18 and 19 strand compacted wire rope, provides higher strength in a smaller diameter, and resistance to drum crushing.

|

Nominal Diameter |

6 Strand |

** 19 X 19 and 18 X 19 |

||

|---|---|---|---|---|

|

Minimum Breaking Load |

Approx. Mass |

Minimum Breaking Load |

Approx. Mass |

|

|

3/ 18 |

8.30 |

.31 |

8.30 |

.31 |

|

7/16 |

11.2 |

.39 |

11.2 |

.40 |

|

1/2 |

14.6 |

.49 |

14.6 |

.54 |

|

9/16 |

18.5 |

.63 |

18.5 |

.69 |

|

5/8 |

22.7 |

.78 |

22.7 |

.85 |

|

3/4 |

32.4 |

1.13 |

32.4 |

1.25 |

|

7/8 |

43.8 |

1.54 |

43.8 |

1.68 |

|

1 |

56.9 |

2.00 |

56.9 |

2.17 |

|

1 1/8 |

71.5 |

2.54 |

71.5 |

2.75 |

|

1 1/4 |

87.9 |

3.14 |

87.9 |

3.45 |

|

1 3/8 |

106 |

3.80 |

106 |

4.33 |

|

1 1/2 |

125 |

4.50 |

125 |

5.11 |

Breaking loads listed are the minimum established by the Wire Rope Technical Board. Verify the breaking load when inquiring as actual inventories may have different breaking loads.

** The given strengths for 19 strand rotation resistant wire ropes are applicable only when a test is conduced on a new rope fixed at both ends. When the rope is in use and one end is free to rotate. the nominal strength is reduced.

Not recommended for use with swivels.

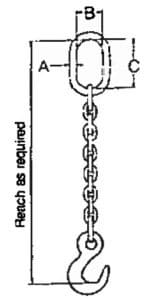

- Single Leg

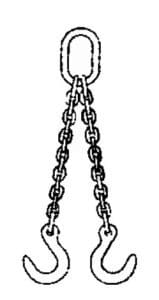

- 2-leg

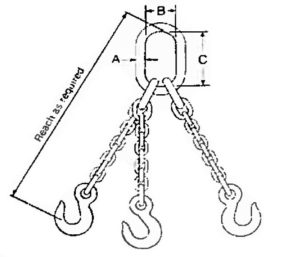

- 3-leg

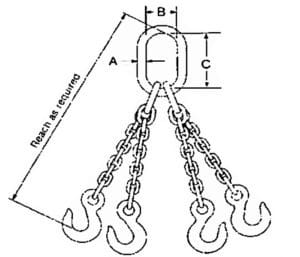

- 4-leg

- Braided Slings

- End Fittings

- Mechanically Swaged

- Poured Sockets

- Open/Closed Swaged

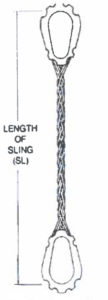

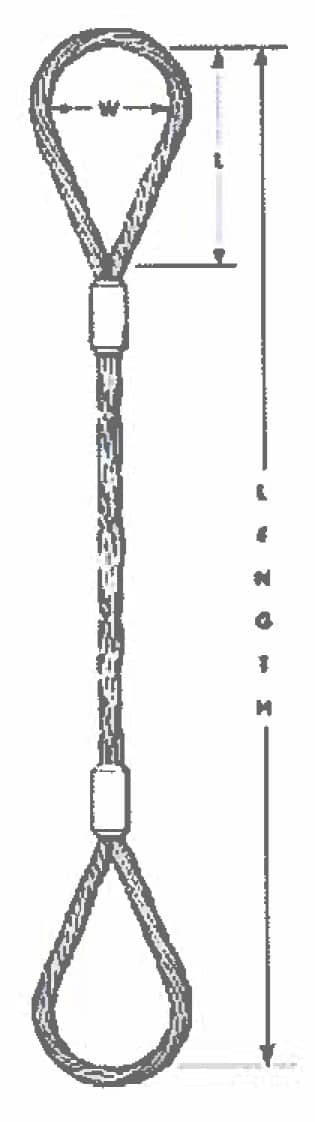

Flemished Eye and Mechanically Swaged

| Diam. Of Wire Rope Inches | Min. Length (SL) Of Sling Ft.-In. | Inside Loop Dimensions | Rated Capacity in Tons (2000 lbs.) | |||

|---|---|---|---|---|---|---|

| EIPS-IWRC | ||||||

| Single Leg Vertical | Choker Hitch | Vertical Basket Hitch** | ||||

| W Inches | L Inches | |||||

|

1/4 |

1-6 |

2 |

4 |

.65 |

.48 |

1.3 |

|

5/16 |

1-9 |

2 1/2 |

5 |

1.00 |

.74 |

2.0 |

|

3/8 |

2-0 |

3 |

6 |

1.40 |

1.10 |

2.9 |

|

7/16 |

2-3 |

3 1/2 |

7 |

1.90 |

1.40 |

3.9 |

|

1/2 |

2-6 |

4 |

8 |

2.50 |

1.90 |

5.1 |

|

9/16 |

2-9 |

4 1/2 |

9 |

3.20 |

2.40 |

6.4 |

|

5/8 |

3-0 |

5 |

10 |

3.90 |

2.90 |

7.8 |

|

3/4 |

3-6 |

6 |

12 |

5.60 |

4.10 |

11.0 |

|

7/8 |

4-0 |

7 |

14 |

7.60 |

5.60 |

15.0 |

|

1 |

4-6 |

8 |

16 |

9.80 |

7.20 |

20.0 |

|

1 1/8 |

5-0 |

9 |

18 |

12.00 |

9.10 |

24.0 |

|

1 1/4 |

5-6 |

10 |

20 |

15.00 |

11.00 |

30.0 |

|

1 3/8 |

6-0 |

11 |

22 |

18.00 |

13.00 |

36.0 |

|

1 1/2 |

7-0 |

12 |

24 |

21.00 |

16.00 |

42.0 |

|

1 5/8 |

4-6 |

13 |

26 |

24.00 |

18.00 |

49.0 |

|

1 3/4 |

8-0 |

14 |

28 |

28.00 |

21.00 |

57.0 |

|

2 |

9-0 |

16 |

32 |

37.00 |

28.00 |

73.0 |

|

2 1/4 |

10-0 |

18 |

36 |

44.00 |

35.00 |

89.0 |

|

2 1/2 |

11-0 |

20 |

40 |

54.00 |

42.00 |

109.0 |

|

2 3/4 |

12-0 |

22 |

44 |

65.00 |

51.00 |

130.0 |

|

3 |

13-0 |

24 |

48 | 77.00 |

60.00 |

153.0 |

|

3 1/2 |

19-8 |

36 |

72 |

102.00 |

79.00 |

203.0 |

|

4 |

23-8 |

45 |

90 |

130.00 |

97.00 |

259.0 |

| Wire Rope Diam. Inches | Heavy Duty Thimble | Alloy Hook Size-Tons | Carbon Shackle Size-Inches | Open Swagged Socket | Closed Swaged Socket | |||

|---|---|---|---|---|---|---|---|---|

| Inside | For EIPS | For EIPS | Pin Size Inches | Jaw Size Inches | Hole Diam. Inches | Head Thickness Inches | ||

| Width Inches | Length Inches | |||||||

| 6 x 19 WITH I. W. R. C. | ||||||||

| 1/4 | 7/8 | 1 5/8 | 1 | 5/16 | 11/16 | 11/16 | 3/4 | 1/2 |

| 5/16 | 1 1/16 | 1 7/8 | 1 1/2 | 3/8 | 13/16 | 13/16 | 7/8 | 11/16 |

| 3/8 | 1 1/8 | 2 1/8 | 2 | 7/16 | 13/16 | 13/16 | 7/8 | 11/16 |

| 7/16 | 1 1/4 | 2 3/8 | 3 | 1/2 | 1 | 1 | 1 1/16 | 7/8 |

| 1/2 | 1 1/2 | 2 3/4 | 5 | 5/8 | 1 | 1 | 1 1/16 | 7/8 |

| 9/16 | 1 1/2 | 2 3/4 | 5 | 5/8 | 1 3/16 | 1 1/4 | 1 1/4 | 1 1/8 |

| 5/8 | 1 3/4 | 3 1/4 | 7 | 3/4 | 1 3/16 | 1 1/4 | 1 1/4 | 1 1/8 |

| 3/4 | 2 | 3 3/4 | 11 | 7/8 | 1 3/8 | 1 1/2 | 1 7/16 | 1 5/16 |

| 7/8 | 2 1/4 | 4 1/4 | 11 | 1 | 1 5/8 | 1 3/4 | 1 11/16 | 1 1/2 |

| 1 | 2 1/2 | 4 1/2 | 15 | 1 1/4 | 2 | 2 | 2 1/16 | 1 3/4 |

| 1 1/8 | 2 7/8 | 5 1/8 | 22 | 1 1/4 | 2 1/4 | 2 1/4 | 2 5/16 | 2 |

| 6 x 37 WITH I. W. R. C. | ||||||||

| 1 1/4 | 3 1/2 | 6 1/2 | 22 | 1 1/2 | 2 1/2 | 2 1/2 | 2 9/16 | 2 1/4 |

| 1 3/8 | 3 1/2 | 6 1/4 | 30 | 1 3/4 | 2 1/2 | 2 1/2 | 2 9/16 | 2 1/4 |

| 1 1/2 | 3 1/2 | 6 1/4 | 30 | 1 3/4 | 2 3/4 | 3 | 2 13/16 | 2 1/2 |

| 1 5/8 | 4 | 8 | 30 | 1 3/4 | - | - | - | - |

| 1 3/4 | 4 1/2 | 9 | 37 | 2 | 3 1/2 | 3 1/2 | 3 9/16 | 3 |

| 2 | 6 | 12 | 60 | 2 1/2 | 3 3/4 | 4 | 3 13/16 | 3 1/4 |

| 2 1/4 | 7 | 14 | 60 | 2 1/2 | - | - | - | - |

| 2 1/2 | 8 1/2 | 15 3/4 | - | 2 1/2 | - | - | - | - |

| 2 3/4 | - | - | - | 3 | - | - | - | - |

| 3 | - | - | - | 3 | - | - | - | - |

| 3 1/2 | - | - | - | 3 1/2 | - | - | - | - |

| 4 | - | - | - | 4 | - | - | - | - |

Design Factor 5:1

* Rated capacities of choker hitches apply when the angle of choke is greater than 135°.

**Rated capacities of basket hitches are based on a minimum diameter of curvature at the point of load contact of 20 times the rope diameter.

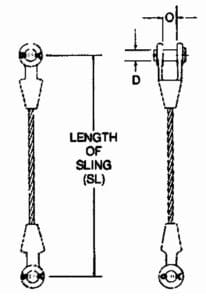

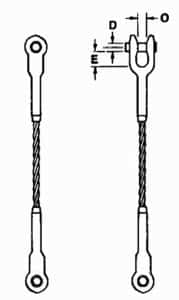

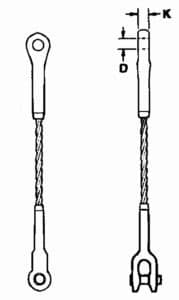

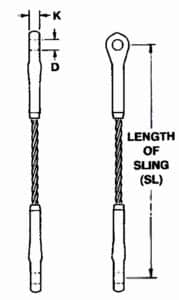

|

Diameter Of Wire Rope Inches |

Minimum Length (SL) Of Sling |

Rated Capacities in Tons (2,000 lbs.) |

Important Dimensions |

||||||

|---|---|---|---|---|---|---|---|---|---|

|

Open Socket |

Closed Socket |

||||||||

|

Single Part Vertical |

Vertical Basket |

O |

D |

W |

L |

K |

|||

|

1/4 |

1-0 |

.68 |

1.3 |

11/16 |

11/16 |

13/16 |

1 3/4 |

1/2 |

|

|

5/16 |

1-0 |

1.10 |

1.9 |

13/16 |

13/16 |

15/16 |

2 |

11/16 |

|

|

3/8 |

1-0 |

1.50 |

2.8 |

13/16 |

13/16 |

15/16 |

2 |

11/16 |

|

|

7/16 |

1-2 |

2.00 |

3.8 |

1 |

1 |

1 1/8 |

2 1/4 |

7/8 |

|

|

1/2 |

1-3 |

2.70 |

4.9 |

1 |

1 |

1 1/8 |

2 1/4 |

7/8 |

|

|

9/16 |

1-5 |

3.40 |

6.2 |

1 1/4 |

1 3/16 |

1 3/8 |

2 1/2 |

1 |

|

|

5/8 |

1-6 |

4.10 |

7.6 |

1 1/4 |

1 3/16 |

1 3/8 |

2 1/2 |

1 |

|

|

3/4 |

1-9 |

5.90 |

11 |

1 1/2 |

1 3/8 |

1 5/8 |

3 |

1 1/4 |

|

|

7/8 |

2-0 |

8.00 |

15 |

1 3/4 |

1 5/8 |

1 7/8 |

3 1/2 |

1 1/2 |

|

|

1 |

2-6 |

10.00 |

19 |

2 |

2 |

2 1/4 |

4 |

1 3/4 |

|

|

1 1/8 |

2-9 |

13.00 |

24 |

2 1/4 |

2 1/4 |

2 1/2 |

4 1/2 |

2 |

|

|

1 1/4 |

3-0 |

16.00 |

30 |

2 1/2 |

2 1/2 |

2 3/4 |

5 |

2 1/4 |

|

|

1 3/8 |

3-0 |

19.00 |

36 |

2 1/2 |

2 1/2 |

2 3/4 |

5 |

2 1/4 |

|

|

1 1/2 |

3-3 |

23.00 |

42 |

3 |

2 3/4 |

3 1/8 |

6 |

2 1/2 |

|

|

1 5/8 |

3-9 |

26.00 |

49 |

3 |

3 |

3 1/4 |

6 1/2 |

2 3/4 |

|

|

1 3/4 |

4-3 |

31.00 |

57 |

3 1/2 |

3 1/2 |

3 17/32 |

7 9/16 |

3 |

|

|

2 |

4-9 |

39.00 |

73 |

4 |

3 3/4 |

3 25/32 |

8 9/16 |

3 1/4 |

|

|

2 1/4 |

5-0 |

49.00 |

91 |

4 1/2 |

4 1/4 |

4 9/32 |

9 1/2 |

3 5/8 |

|

|

2 1/2 |

5-9 |

60.00 |

112 |

5 |

4 3/4 |

5 1/2 |

10 5/8 |

4 |

|

|

2 3/4 |

6-5 |

72.00 |

134 |

5 1/4 |

5 |

6 1/2 |

11 1/4 |

4 7/8 |

|

|

3 |

6-10 |

85.00 |

157 |

5 3/4 |

5 1/4 |

6 3/4 |

11 3/4 |

5 1/4 |

|

|

3 1/4 |

7-7 |

98.00 |

182 |

6 1/4 |

5 1/2 |

7 1/4 |

12 1/4 |

5 3/4 |

|

|

3 1/2 |

8-2 |

113.00 |

209 |

6 3/4 |

6 |

7 3/4 |

13 |

6 1/4 |

|

|

3 3/4 |

8-8 |

128.00 |

235 |

7 1/2 |

7 |

8 1/4 |

14 |

7 |

|

|

4 |

9-1 |

143.00 |

263 |

7 1/2 |

7 |

8 1/4 |

14 |

7 |

|

|

Design Factor 5:1 |

|||||||||

|

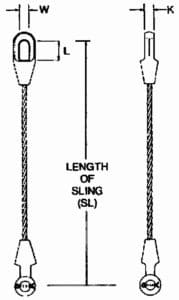

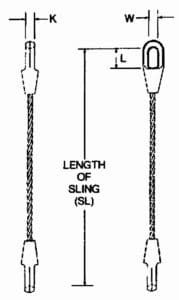

Diameter Of Wire Rope Inches |

Minimum Length (SL) Of Sling |

Rated Capacities in Tons (2,000 lbs.) |

Important Dimensions |

||||||

|---|---|---|---|---|---|---|---|---|---|

|

Open Swage Socket |

Closed Swage Socket |

||||||||

|

Single Part Vertical |

Vertical Basket |

O |

D |

W |

L |

K |

|||

|

1/4 |

0-11 |

.68 |

1.3 |

11/16 |

11/16 |

1 5/32 |

1/2 |

3/4 |

|

|

5/16 |

1-1 |

1.10 |

1.9 |

13/16 |

13/16 |

1 11/32 |

11/16 |

7/8 |

|

|

3/8 |

1-3 |

1.50 |

2.8 |

13/16 |

13/16 |

1 11/32 |

11/16 |

7/8 |

|

|

7/16 |

1-6 |

2.00 |

3.8 |

1 |

1 |

1 1/2 |

7/8 |

1 1/16 |

|

|

1/2 |

1-8 |

2.70 |

4.9 |

1 |

1 |

1 1/2 |

7/8 |

1 1/16 |

|

|

9/16 |

1-10 |

3.40 |

6.2 |

1 1/4 |

1 3/16 |

1 21/32 |

1 1/8 |

1 1/4 |

|

|

5/8 |

2-0 |

4.10 |

7.6 |

1 1/4 |

1 3/16 |

1 21/32 |

1 1/8 |

1 1/4 |

|

|

3/4 |

2-5 |

5.90 |

11 |

1 1/2 |

1 3/8 |

2 1/16 |

1 5/16 |

1 7/16 |

|

|

7/8 |

2-10 |

8.00 |

15 |

1 3/4 |

1 5/8 |

2 7/16 |

1 1/2 |

1 11/16 |

|

|

1 |

3-2 |

10.00 |

19 |

2 |

2 |

2 3/4 |

1 3/4 |

2 1/16 |

|

|

1 1/8 |

3-7 |

13.00 |

24 |

2 1/4 |

2 1/4 |

3 1/8 |

2 |

2 5/16 |

|

|

1 1/4 |

4-0 |

16.00 |

30 |

2 1/2 |

2 1/2 |

3 1/2 |

2 1/4 |

2 9/16 |

|

|

1 3/8 |

4-5 |

19.00 |

36 |

2 1/2 |

2 1/2 |

4 |

2 1/4 |

2 9/16 |

|

|

1 1/2 |

4-9 |

23.00 |

42 |

3 |

2 3/4 |

4 3/8 |

2 1/2 |

2 13/16 |

|

|

1 3/4 |

5-5 |

31.00 |

57 |

3 1/2 |

3 1/2 |

5 |

3 |

3 9/16 |

|

|

2 |

6-4 |

39.00 |

73 |

4 |

3 3/4 |

6 1/8 |

3 1/4 |

3 13/16 |

|

|

2 1/4 |

7-2 |

49.00 |

91 |

4 1/2 |

4 1/4 |

4 5/8 |

4 |

4 5/16 |

|

|

2 1/2 |

8-0 |

60.00 |

112 |

4 1/2 |

4 1/4 |

4 5/8 |

4 |

4 5/16 |

|

|

Design Factor 5:1 |

|||||||||

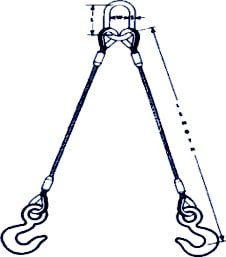

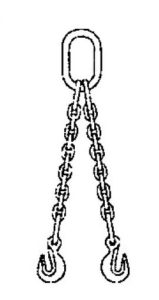

2-Leg - Type 21

FLEMISHED EYE AND MECHANICALLY SWAGED

Type 21 slings are 2-leg All-Purpose bridles, designed for general lifting purposes where attachment may be made directly to the load, such as hooking into lifting eyes or placing loops over lugs.

|

Diameter Of Wire Rope |

Minimum Length (SL) Of Sling |

Rated Capacities in Tons |

Alloy Links |

||||||

|---|---|---|---|---|---|---|---|---|---|

|

60° |

45° |

30° |

|||||||

|

1/4 |

1-3 |

1.10 |

.91 |

.65 |

1/2 |

||||

|

5/16 |

1-6 |

1.70 |

1.40 |

1.00 |

1/2 |

||||

|

3/8 |

1-8 |

2.50 |

2.00 |

1.40 |

3/4 |

||||

|

7/16 |

1-10 |

3.40 |

2.70 |

1.90 |

7/8 |

||||

|

1/2 |

2-0 |

4.40 |

3.60 |

2.50 |

1 |

||||

|

9/16 |

2-2 |

5.50 |

4.50 |

3.20 |

1 1/4 |

||||

|

5/8 |

2-4 |

6.80 |

5.50 |

3.90 |

1 1/4 |

||||

|

3/4 |

2-9 |

9.70 |

7.90 |

5.60 |

1 1/4 |

||||

|

7/8 |

3-3 |

13.00 |

11.00 |

7.60 |

1 1/2 |

||||

|

1 |

3-6 |

17.00 |

14.00 |

9.80 |

1 1/2 |

||||

|

1 1/8 |

4-0 |

21.00 |

17.00 |

12.00 |

1 3/4 |

||||

|

1 1/4 |

4-6 |

26.00 |

21.00 |

15.00 |

2 |

||||

|

1 3/8 |

5-0 |

31.00 |

25.00 |

18.00 |

2 |

||||

|

1 1/2 |

5-6 |

37.00 |

30.00 |

21.00 |

2 1/4 |

||||

|

1 5/8 |

6-0 |

42.00 |

35.00 |

24.00 |

2 1/2 |

||||

|

1 3/4 |

6-6 |

49.00 |

40.00 |

28.00 |

2 1/2 |

||||

|

2 |

8-0 |

63.00 |

52.00 |

37.00 |

2 3/4 |

||||

|

2 1/4 |

8-9 |

77.00 |

63.00 |

44.00 |

3 1/4 |

||||

|

2 1/2 |

10-0 |

94.00 |

77.00 |

54.00 |

3 3/4 |

||||

|

Design Factor 5:1 |

|||||||||

|

Wire Rope Diam. |

Standard Loop Inside |

Heavy Duty Thimble Inside |

Alloy Hook Size-Tons |

Carbon Shackle With Thimble Size-Inches |

Open Swaged Socket |

Closed Swaged Socket |

||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Pin Size |

Jaw Size |

Hole Diam. |

Head Opening |

|||||||

|

Width Inches |

Length Inches |

Width Inches |

Length Inches |

|||||||

|

6 x 19 WITH I. W. R. C. |

||||||||||

|

1/4 |

2 |

4 |

7/8 |

1 5/8 |

1 |

5/16 |

11/16 |

11/16 |

3/4 |

1/2 |

|

5/16 |

2 1/2 |

5 |

1 1/16 |

1 7/8 |

1 1/2 |

3/8 |

13/16 |

13/16 |

7/8 |

11/16 |

|

3/8 |

3 |

6 |

1 1/8 |

2 1/8 |

2 |

7/16 |

13/16 |

13/16 |

7/8 |

11/16 |

|

7/16 |

3 1/2 |

7 |

1 1/4 |

2 3/8 |

3 1/2 |

1 |

1 |

1 |

1/16 |

7/8 |

|

1/2 |

4 |

8 |

1 1/2 |

2 3/4 |

5 |

5/8 |

1 |

1 |

1 1/16 |

7/8 |

|

9/16 |

4 1/2 |

9 |

1 1/2 |

2 3/4 |

5 |

5/8 |

1 3/16 |

1 1/4 |

1 1/4 |

1 1/8 |

|

5/8 |

5 |

10 |

1 3/4 |

3 1/4 |

7 |

3/4 |

1 3/16 |

1 1/4 |

1 1/4 |

1 1/8 |

|

3/4 |

6 |

12 |

2 |

3 3/4 |

11 |

7/8 |

1 3/8 |

1 1/2 |

1 7/16 |

1 5/16 |

|

7/8 |

7 |

14 |

2 1/4 |

4 1/4 |

11 |

1 |

1 5/8 |

1 3/4 |

1 11/16 |

1 1/2 |

|

1 |

8 |

16 |

2 1/2 |

4 1/2 |

15 |

1 1/4 |

2 |

2 |

2 1/16 |

1 3/4 |

|

1 1/8 |

9 |

18 |

2 7/8 |

5 1/8 |

22 |

1 1/4 |

2 1/4 |

2 1/4 |

2 5/16 |

2 |

|

6 x 37 WITH I. W. R. C. |

||||||||||

|

1 1/4 |

10 |

20 |

2 7/8 |

5 1/8 |

22 |

1 1/2 |

2 1/2 |

2 1/2 |

2 9/16 |

2 1/4 |

|

1 3/8 |

11 |

22 |

3 1/2 |

6 1/4 |

30 |

1 3/4 |

2 1/2 |

2 1/2 |

2 9/16 |

2 1/4 |

|

1 1/2 |

12 |

24 |

3 1/2 |

6 1/4 |

30 |

1 3/4 |

2 3/4 |

3 |

2 13/16 |

2 1/2 |

|

1 5/8 |

13 |

26 |

4 |

8 |

30 |

1 3/4 |

3 1/2 |

3 1/2 |

3 9/16 |

3 |

|

1 3/4 |

14 |

28 |

4 1/2 |

9 |

37 |

2 |

3 1/2 |

3 1/2 |

3 9/16 |

3 |

|

2 |

16 |

32 |

6 |

12 |

60 |

2 1/2 |

3 3/4 |

4 |

3 13/16 |

3 1/4 |

|

2 1/4 |

18 |

36 |

7 |

14 |

60 |

2 1/2 |

4 1/4 |

4 1/4 |

4 5/16 |

4 |

|

2 1/2 |

20 |

40 |

- |

- |

- |

3 |

4 1/4 |

4 1/4 |

4 5/16 |

4 |

|

2 3/4 |

22 |

44 |

- |

- |

- |

3 |

- |

- |

- |

- |

|

3 |

24 |

48 |

- |

- |

- |

3 |

- |

- |

- |

- |

|

3 1/4 |

- |

- |

- |

- |

- |

3 1/2 |

- |

- |

- |

- |

|

3 1/2 |

- |

- |

- |

- |

- |

3 1/2 |

- |

- |

- |

- |

|

3 3/4 |

- |

- |

- |

- |

- |

4 |

- |

- |

- |

- |

|

4 |

- |

- |

- |

- |

- |

4 |

- |

- |

- |

- |

|

Fittings dimensions subject

to change without notice. |

||||||||||

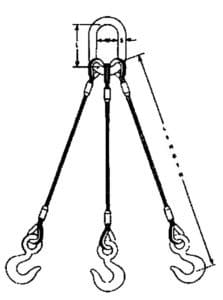

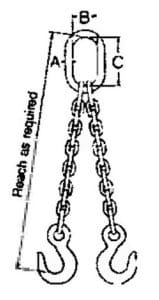

3-Leg - Type 31

FLEMISHED EYE AND MECHANICALLY SWAGED

Type 31 slings are 3-leg All-Purpose bridles, generally recommended for handling unbalanced loads. Confirm fittings details when inquiring.

|

Diameter Of Wire Rope |

Minimum Length (SL) |

Rated Capacities in Tons |

Alloy Links |

||||||

|---|---|---|---|---|---|---|---|---|---|

|

60° |

45° |

30° |

|||||||

|

1/4 |

1-3 |

1.70 |

1.40 |

.97 |

1/2 |

||||

|

5/16 |

1-6 |

2.60 |

2.10 |

1.50 |

5/8 |

||||

|

3/8 |

1-8 |

3.70 |

3.00 |

2.20 |

3/4 |

||||

|

7/16 |

1-10 |

5.00 |

4.10 |

2.90 |

1 |

||||

|

1/2 |

2-0 |

6.60 |

5.40 |

3.80 |

1 |

||||

|

9/16 |

2-2 |

8.30 |

6.80 |

4.80 |

1 1/4 |

||||

|

5/8 |

2-4 |

10.00 |

8.30 |

5.90 |

1 1/4 |

||||

|

3/4 |

2-9 |

15.00 |

12.00 |

8.40 |

1 1/2 |

||||

|

7/8 |

3-3 |

20.00 |

16.00 |

11.00 |

1 3/4 |

||||

|

1 |

3-6 |

26.00 |

21.00 |

15.00 |

2 |

||||

|

1 1/8 |

4-0 |

31.00 |

26.00 |

18.00 |

2 |

||||

|

1 1/4 |

4-6 |

38.00 |

31.00 |

22.00 |

2 1/4 |

||||

|

1 3/8 |

5-0 |

46.00 |

38.00 |

27.00 |

2 1/2 |

||||

|

1 1/2 |

5-6 |

55.00 |

45.00 |

32.00 |

2 3/4 |

||||

|

1 5/8 |

6-0 |

63.00 |

52.00 |

37.00 |

2 3/4 |

||||

|

1 3/4 |

6-6 |

74.00 |

60.00 |

42.00 |

3 |

||||

|

2 |

8-0 |

95.00 |

78.00 |

55.00 |

3 1/2 |

||||

|

2 1/4 |

8-9 |

116.00 |

94.00 |

67.00 |

4 |

||||

|

2 1/2 |

10-0 |

141.00 |

115.00 |

82.00 |

4 1/2 |

||||

|

Design Factor 5:1 |

|||||||||

|

Wire Rope Diam. Inches |

Standard Loop Inside |

Heavy Duty Thimble Inside |

Alloy Hook Size-Tons For |

Carbon Shackle With Thimble |

Open Swaged Socket |

Closed Swaged Socket |

||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Width Inches |

Length Inches |

Width Inches |

Length Inches |

Pin Size Inches |

Jaw Size Inches |

Hole Diam. Inches |

Head Opening Inches |

|||

|

6 x 19 WITH I. W. R. C. |

||||||||||

|

1/4 |

2 |

4 |

7/8 |

1 5/8 |

1 |

5/16 |

11/16 |

11/16 |

3/4 |

1/2 |

|

5/16 |

2 1/2 |

5 |

1 1/16 |

1 7/8 |

1 1/2 |

3/8 |

13/16 |

13/16 |

7/8 |

11/16 |

|

3/8 |

3 |

6 |

1 1/8 |

2 1/8 |

2 |

7/16 |

13/16 |

13/16 |

7/8 |

11/16 |

|

7/16 |

3 1/2 |

7 |

1 1/4 |

2 3/8 |

3 |

1/2 |

1 |

1 |

1 1/16 |

7/8 |

|

1/2 |

4 |

8 |

1 1/2 |

2 3/4 |

5 |

5/8 |

1 |

1 |

1 1/16 |

7/8 |

|

9/16 |

4 1/2 |

9 |

1 1/2 |

2 3/4 |

5 |

5/8 |

1 3/16 |

1 1/4 |

1 1/4 |

1 1/8 |

|

5/8 |

5 |

10 |

1 3/4 |

3 1/4 |

7 |

3/4 |

1 3/16 |

1 1/4 |

1 1/4 |

1 1/8 |

|

3/4 |

6 |

12 |

2 |

3 3/4 |

11 |

7/8 |

1 3/8 |

1 1/2 |

1 7/16 |

1 5/16 |

|

7/8 |

7 |

14 |

2 1/4 |

4 1/4 |

11 |

1 |

1 5/8 |

1 3/4 |

1 11/16 |

1 1/2 |

|

1 |

8 |

16 |

2 1/2 |

4 1/2 |

15 |

1 1/4 |

2 |

2 |

2 1/16 |

1 3/4 |

|

1 1/8 |

9 |

18 |

2 7/8 |

5 1/8 |

22 |

1 1/4 |

2 1/4 |

2 1/4 |

2 5/16 |

2 |

|

6 x 37 WITH I. W. R. C. |

||||||||||

|

1 1/4 |

10 |

20 |

2 7/8 |

5 1/8 |

22 |

1 1/2 |

2 1/2 |

2 1/2 |

2 9/16 |

2 1/4 |

|

1 3/8 |

11 |

22 |

3 1/2 |

6 1/4 |

30 |

1 3/4 |

2 1/2 |

2 1/2 |

2 9/16 |

2 1/4 |

|

1 1/2 |

12 |

24 |

3 1/2 |

6 1/4 |

30 |

1 3/4 |

2 3/4 |

3 |

2 13/16 |

2 1/2 |

|

1 5/8 |

13 |

26 |

4 |

8 |

30 |

1 3/4 |

3 1/2 |

3 1/2 |

3 9/16 |

3 |

|

1 3/4 |

14 |

28 |

4 1/2 |

9 |

37 |

2 |

3 1/2 |

3 1/2 |

3 9/16 |

3 |

|

2 |

16 |

32 |

6 |

12 |

60 |

2 1/2 |

3 3/4 |

4 |

3 13/16 |

3 1/4 |

|

2 1/4 |

18 |

36 |

7 |

14 |

60 |

2 1/2 |

4 1/4 |

4 1/4 |

4 5/16 |

4 |

|

2 1/2 |

20 |

40 |

- |

- |

- |

3 |

4 1/4 |

4 1/4 |

4 5/16 |

4 |

|

2 3/4 |

- |

- |

- |

- |

- |

3 |

- |

- |

- |

- |

|

3 |

- |

- |

- |

- |

- |

3 |

- |

- |

- |

- |

|

3 1/4 |

- |

- |

- |

- |

- |

3 1/2 |

- |

- |

- |

- |

|

3 1/2 |

- |

- |

- |

- |

- |

3 1/2 |

- |

- |

- |

- |

|

3 3/4 |

- |

- |

- |

- |

- |

4 |

- |

- |

- |

- |

|

4 |

- |

- |

- |

- |

- |

4 |

- |

- |

- |

- |

|

Design Factor 5:1 |

||||||||||

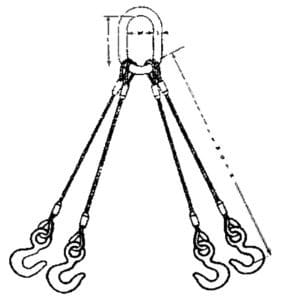

4-Leg - Type 41

FLEMISHED EYE AND MECHANICALLY SWAGED

Type 41 slings are 4-leg All-Purpose bridles, used both for balanced and unbalanced loads and for heavier loads where design calls for more distribution of weight by the use of attachment at four points.

|

Diameter Of Wire Rope |

Minimum Length (SL) Of Sling |

Rated Capacities in Tons |

Alloy Links Diam. Inches |

||||||

|---|---|---|---|---|---|---|---|---|---|

|

60° |

45° |

30° |

|||||||

|

1/4 |

1-3 |

2.20 |

1.80 |

1.30 |

5/8 |

||||

|

5/16 |

1-6 |

3.50 |

2.80 |

2.00 |

3/4 |

||||

|

3/8 |

1-8 |

5.00 |

4.10 |

2.90 |

7/8 |

||||

|

7/16 |

1-10 |

6.70 |

5.50 |

3.90 |

1 |

||||

|

1/2 |

2-0 |

8.80 |

7.10 |

5.10 |

1 1/4 |

||||

|

9/16 |

2-2 |

11.00 |

9.00 |

6.40 |

1 1/2 |

||||

|

5/8 |

2-4 |

14.00 |

11.00 |

7.80 |

1 1/2 |

||||

|

3/4 |

2-9 |

19.00 |

16.00 |

11.00 |

1 3/4 |

||||

|

7/8 |

3-3 |

26.00 |

21.00 |

15.00 |

2 |

||||

|

1 |

3-6 |

34.00 |

28.00 |

20.00 |

2 1/4 |

||||

|

1 1/8 |

4-0 |

42.00 |

34.00 |

24.00 |

2 1/2 |

||||

|

1 1/4 |

4-6 |

51.00 |

42.00 |

30.00 |

2 1/2 |

||||

|

1 3/8 |

5-0 |

62.00 |

50.00 |

36.00 |

3 1/4 |

||||

|

1 1/2 |

5-6 |

73.00 |

60.00 |

42.00 |

3 3/4 |

||||

|

1 5/8 |

6-0 |

85.00 |

69.00 |

49.00 |

3 3/4 |

||||

|

1 3/4 |

6-6 |

98.00 |

80.00 |

57.00 |

4 1/2 |

||||

|

2 |

8-0 |

127.00 |

104.00 |

73.00 |

4 1/2 |

||||

|

2 1/4 |

8-9 |

154.00 |

126.00 |

89.00 |

Call |

||||

|

2 1/2 |

10-0 |

188.00 |

154.00 |

109.00 |

Call |

||||

|

Design Factor 5:1 |

|||||||||

|

Wire Rope Diam. Inches |

Standard Loop Inside |

Heavy Duty Thimble Inside |

Alloy Hook Size-Tons For EIPS |

Carbon Shackle With Thimble Size-Inches For EIPS |

Open Swaged Socket |

Closed Swaged Socket |

||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Width Inches |

Length Inches |

Width Inches |

Length Inches |

Pin Size Inches |

Jaw Size Inches |

Hole Diam. Inches |

Head Opening Inches |

|||

|

6 x 19 WITH I. W. R. C. |

||||||||||

|

1/4 |

2 |

4 |

7/8 |

1 5/8 |

1 |

5/16 |

11/16 |

11/16 |

3/4 |

1/2 |

|

5/16 |

2 1/2 |

5 |

1 1/16 |

1 7/8 |

1 1/2 |

3/8 |

13/16 |

13/16 |

7/8 |

11/16 |

|

3/8 |

3 |

6 |

1 1/8 |

2 1/8 |

2 |

7/16 |

13/16 |

13/16 |

7/8 |

11/16 |

|

7/16 |

3 1/2 |

7 |

1 1/4 |

2 3/8 |

3 |

1/2 |

1 |

1 |

1 1/16 |

7/8 |

|

1/2 |

4 |

8 |

1 1/2 |

2 3/4 |

5 |

5/8 |

1 |

1 |

1 1/16 |

7/8 |

|

9/16 |

4 1/2 |

9 |

1 1/2 |

2 3/4 |

5 |

5/8 |

1 3/16 |

1 1/4 |

1 1/4 |

1 1/8 |

|

5/8 |

5 |

10 |

1 3/4 |

3 1/4 |

7 |

3/4 |

1 3/16 |

1 1/4 |

1 1/4 |

1 1/8 |

|

3/4 |

6 |

12 |

2 |

3 3/4 |

11 |

7/8 |

1 3/8 |

1 1/2 |

1 7/16 |

1 5/16 |

|

7/8 |

7 |

14 |

2 1/4 |

4 1/4 |

11 |

1 |

1 5/8 |

1 3/4 |

1 11/16 |

1 1/2 |

|

1 |

8 |

16 |

2 1/2 |

4 1/2 |

15 |

1 1/4 |

2 |

2 |

2 1/16 |

1 3/4 |

|

1 1/8 |

9 |

18 |

2 7/8 |

5 1/8 |

22 |

1 1/4 |

2 1/4 |

2 1/4 |

2 5/16 |

2 |

|

6 x 37 WITH I. W. R. C. |

||||||||||

|

1 1/4 |

10 |

20 |

2 7/8 |

5 1/8 |

22 |

1 1/2 |

2 1/2 |

2 1/2 |

2 9/16 |

2 1/4 |

|

1 3/8 |

11 |

22 |

3 1/2 |

6 1/4 |

30 |

1 3/4 |

2 1/2 |

2 1/2 |

2 9/16 |

2 1/4 |

|

1 1/2 |

12 |

24 |

3 1/2 |

6 1/4 |

30 |

1 3/4 |

2 3/4 |

3 |

2 13/16 |

2 1/2 |

|

1 5/8 |

13 |

26 |

4 |

8 |

30 |

1 3/4 |

3 1/2 |

3 1/2 |

3 9/16 |

3 |

|

1 3/4 |

14 |

28 |

4 1/2 |

9 |

37 |

2 |

3 1/2 |

3 1/2 |

3 9/16 |

3 |

|

2 |

16 |

32 |

6 |

12 |

60 |

2 1/2 |

3 3/4 |

4 |

3 13/16 |

3 1/4 |

|

2 1/4 |

18 |

36 |

7 |

14 |

60 |

2 1/2 |

4 1/4 |

4 1/4 |

4 5/16 |

4 |

|

2 1/2 |

20 |

40 |

- |

- |

- |

3 |

4 1/4 |

4 1/4 |

4 5/16 |

4 |

|

2 3/4 |

- |

- |

- |

- |

- |

3 |

- |

- |

- |

- |

|

3 |

- |

- |

- |

- |

- |

3 |

- |

- |

- |

- |

|

3 1/4 |

- |

- |

- |

- |

- |

3 1/2 |

- |

- |

- |

- |

|

3 1/2 |

- |

- |

- |

- |

- |

3 1/2 |

- |

- |

- |

- |

|

3 3/4 |

- |

- |

- |

- |

- |

4 |

- |

- |

- |

- |

|

4 |

- |

- |

- |

- |

- |

4 |

- |

- |

- |

- |

|

Design Factor 5:1 |

||||||||||

- Type 16

- Type 18

- Type 19

|

Diam. of Component Ropes In. |

Min Length (SL) of Slings Ft.-In. |

Rated Capacities in Tons of 2000 lb. |

Length of Loops |

Slip-Thru Thimbles |

Crescent Thimbles |

|||

|---|---|---|---|---|---|---|---|---|

EIPS Rope - IWRC |

||||||||

Single Leg Vertical |

Choker Hitch ** |

Vertical Basket * |

Suggested L In. |

Min. L In. |

Size No. |

Size No. |

||

1/8 |

1-6 |

.84 |

.74 |

1.7 |

6 |

6 |

W-2 |

6C |

3/16 |

2-0 |

1.4 |

1.2 |

2.8 |

8 |

6 |

W-3 |

8C |

1/4 |

2-6 |

2.9 |

2.5 |

4.9 |

12 |

8 |

W-4 |

9C |

5/16 |

2-9 |

3.8 |

3.4 |

7.7 |

12 |

8 |

W-4 |

10C |

3/8 |

3-6 |

5.5 |

4.8 |

11 |

16 |

10 |

W-5 |

16C |

7/16 |

4-0 |

8.6 |

7.5 |

17 |

18 |

12 |

W-6 |

18C |

1/2 |

4-6 |

11 |

9.8 |

22 |

18 |

12 |

W-7 |

20C |

9/16 |

5-6 |

14 |

12 |

28 |

20 |

14 |

W-7 |

22C |

5/8 |

6-6 |

17 |

15 |

35 |

24 |

18 |

W-8 |

24C |

3/4 |

7-6 |

25 |

22 |

49 |

28 |

20 |

W-9 |

32C |

7/8 |

8-9 |

33 |

29 |

67 |

32 |

24 |

W-10 |

40C |

1 |

10-6 |

43 |

38 |

87 |

36 |

30 |

W-10 |

40C |

* Larger sizes available upon request

** Rated capacities or choker hitches apply when the angle of choke is greater than 135°.

Rated capacities basket hitch based on D/d ratio of 25 times the component rope diameter.

Rated capacities based on pin diameter no larger than natural eye width or less than the nominal sling

diameter.

Rated capacities based on design factor of 5.

Horizontal sing angles less than 30 degrees shall not be used.

Standard in 7 x 19 galvanized rope through 3/8″ component ropes.

Braided Slings Type 18

Diameter of Component Rope Inches |

Diameter of Sling Body Inches (Approx). |

Min. Length (SL) of Sling Ft.-In. |

Rated Capacity ** |

Standard Inside Loop Dimensions (Approx.) |

|||

|---|---|---|---|---|---|---|---|

Single Leg Vertical |

*** |

Basket Hitch * |

W Inches |

L Inches |

|||

* 3/32 |

7/16 |

1-5 |

.56 |

.49 |

1.10 |

2 |

4 |

* 1/8 |

9/16 |

1-10 |

1.10 |

1.00 |

2.20 |

3 |

6 |

* 3/16 |

13/16 |

2-10 |

1.90 |

1.60 |

3.70 |

5 |

10 |

* 1/4 |

1 |

1/8 |

3-6 |

3.80 |

3.30 |

6.60 |

12 |

5/16 |

1 3/8 |

4-6 |

5.10 |

4.50 |

10.00 |

8 |

16 |

* 3/8 |

1 11/16 |

5-0 |

7.30 |

6.40 |

15.00 |

8 |

16 |

7/16 |

2 |

5-9 |

11.00 |

10.00 |

23.00 |

9 |

18 |

1/2 |

2 1/4 |

6-5 |

15.00 |

13.00 |

30.00 |

9 |

18 |

9/16 |

2 1/2 |

8-0 |

19.00 |

16.00 |

38.00 |

12 |

24 |

5/8 |

2 13/16 |

9-4 |

23.00 |

20.00 |

46.00 |

14 |

28 |

3/4 |

3 3/8 |

- |

33.00 |

29.00 |

66.00 |

- |

- |

7/8 |

4 |

- |

45.00 |

39.00 |

89.00 |

- |

- |

1 |

4 1/2 |

- |

58.00 |

51.00 |

116.00 |

- |

- |

1 1/8 |

5 |

- |

73.00 |

64.00 |

146.00 |

- |

- |

1 1/4 |

5 5/8 |

- |

89.00 |

78.00 |

179.00 |

- |

- |

1 3/8 |

6 3/18 |

- |

108.00 |

94.00 |

215.00 |

- |

- |

1 1/2 |

6 3/4 |

- |

128.00 |

112.00 |

255.00 |

- |

- |

1 5/8 |

7 5/16 |

- |

148.00 |

129.00 |

296.00 |

- |

- |

1 3/4 |

7 7/8 |

- |

171.00 |

150.00 |

343.00 |

- |

- |

1 7/8 |

8 7/16 |

- |

195.00 |

171.00 |

390.00 |

- |

- |

2 |

9 |

- |

222.00 |

194.00 |

444.00 |

- |

- |

Diameter of Component Rope Inches |

Diameter of Sling Body Inches (Approx). |

Min. Length (SL) of Sling Ft.-In. |

Rated Capacity ** |

Standard Inside Loop Dimensions (Approx.) |

|||

|---|---|---|---|---|---|---|---|

Single Leg Vertical |

*** |

Basket Hitch * |

W Inches |

L Inches |

|||

* 3/32 |

7/16 |

1-5 |

.56 |

.49 |

1.10 |

2 |

4 |

* 1/8 |

9/16 |

1-10 |

1.10 |

1.00 |

2.20 |

3 |

6 |

* 3/16 |

13/16 |

2-10 |

1.90 |

1.60 |

3.70 |

5 |

10 |

* 1/4 |

1 |

1/8 |

3-6 |

3.80 |

3.30 |

6.60 |

12 |

5/16 |

1 3/8 |

4-6 |

5.10 |

4.50 |

10.00 |

8 |

16 |

* 3/8 |

1 11/16 |

5-0 |

7.30 |

6.40 |

15.00 |

8 |

16 |

7/16 |

2 |

5-9 |

11.00 |

10.00 |

23.00 |

9 |

18 |

1/2 |

2 1/4 |

6-5 |

15.00 |

13.00 |

30.00 |

9 |

18 |

9/16 |

2 1/2 |

8-0 |

19.00 |

16.00 |

38.00 |

12 |

24 |

5/8 |

2 13/16 |

9-4 |

23.00 |

20.00 |

46.00 |

14 |

28 |

3/4 |

3 3/8 |

- |

33.00 |

29.00 |

66.00 |

- |

- |

7/8 |

4 |

- |

45.00 |

39.00 |

89.00 |

- |

- |

1 |

4 1/2 |

- |

58.00 |

51.00 |

116.00 |

- |

- |

1 1/8 |

5 |

- |

73.00 |

64.00 |

146.00 |

- |

- |

1 1/4 |

5 5/8 |

- |

89.00 |

78.00 |

179.00 |

- |

- |

1 3/8 |

6 3/18 |

- |

108.00 |

94.00 |

215.00 |

- |

- |

1 1/2 |

6 3/4 |

- |

128.00 |

112.00 |

255.00 |

- |

- |

1 5/8 |

7 5/16 |

- |

148.00 |

129.00 |

296.00 |

- |

- |

1 3/4 |

7 7/8 |

- |

171.00 |

150.00 |

343.00 |

- |

- |

1 7/8 |

8 7/16 |

- |

195.00 |

171.00 |

390.00 |

- |

- |

2 |

9 |

- |

222.00 |

194.00 |

444.00 |

- |

- |

Larger sizes available.

* Standard galvanized 7 x 19 through 3/8″ component ropes.

** Rated capacities of basket hitches are based on minimum diameter of curvature at the point of load

contact of 20 times the rope diameter

*** Rated capacities of choker hitches apply when the angle of choke is greater than 135°.

Diameter of Component Rope Inches |

Diameter of Sling Body Inches (Approx). |

Min. Length (SL) of Sling Ft.-In. |

Rated Capacity ** |

Standard Inside Loop Dimensions (Approx.) |

|||

|---|---|---|---|---|---|---|---|

Single Leg Vertical |

*** |

Basket Hitch * |

W Inches |

L Inches |

|||

* 3/32 |

7/16 |

1-5 |

.56 |

.49 |

1.10 |

2 |

4 |

* 1/8 |

9/16 |

1-10 |

1.10 |

1.00 |

2.20 |

3 |

6 |

* 3/16 |

13/16 |

2-10 |

1.90 |

1.60 |

3.70 |

5 |

10 |

* 1/4 |

1 |

1/8 |

3-6 |

3.80 |

3.30 |

6.60 |

12 |

5/16 |

1 3/8 |

4-6 |

5.10 |

4.50 |

10.00 |

8 |

16 |

* 3/8 |

1 11/16 |

5-0 |

7.30 |

6.40 |

15.00 |

8 |

16 |

7/16 |

2 |

5-9 |

11.00 |

10.00 |

23.00 |

9 |

18 |

1/2 |

2 1/4 |

6-5 |

15.00 |

13.00 |

30.00 |

9 |

18 |

9/16 |

2 1/2 |

8-0 |

19.00 |

16.00 |

38.00 |

12 |

24 |

5/8 |

2 13/16 |

9-4 |

23.00 |

20.00 |

46.00 |

14 |

28 |

3/4 |

3 3/8 |

- |

33.00 |

29.00 |

66.00 |

- |

- |

7/8 |

4 |

- |

45.00 |

39.00 |

89.00 |

- |

- |

1 |

4 1/2 |

- |

58.00 |

51.00 |

116.00 |

- |

- |

1 1/8 |

5 |

- |

73.00 |

64.00 |

146.00 |

- |

- |

1 1/4 |

5 5/8 |

- |

89.00 |

78.00 |

179.00 |

- |

- |

1 3/8 |

6 3/18 |

- |

108.00 |

94.00 |

215.00 |

- |

- |

1 1/2 |

6 3/4 |

- |

128.00 |

112.00 |

255.00 |

- |

- |

1 5/8 |

7 5/16 |

- |

148.00 |

129.00 |

296.00 |

- |

- |

1 3/4 |

7 7/8 |

- |

171.00 |

150.00 |

343.00 |

- |

- |

1 7/8 |

8 7/16 |

- |

195.00 |

171.00 |

390.00 |

- |

- |

2 |

9 |

- |

222.00 |

194.00 |

444.00 |

- |

- |

Diameter of Component Rope Inches |

Diameter of Sling Body Inches (Approx). |

Min. Length (SL) of Sling Ft.-In. |

Rated Capacity ** |

Standard Inside Loop Dimensions (Approx.) |

|||

|---|---|---|---|---|---|---|---|

Single Leg Vertical |

*** |

Basket Hitch * |

W Inches |

L Inches |

|||

* 3/32 |

7/16 |

1-5 |

.56 |

.49 |

1.10 |

2 |

4 |

* 1/8 |

9/16 |

1-10 |

1.10 |

1.00 |

2.20 |

3 |

6 |

* 3/16 |

13/16 |

2-10 |

1.90 |

1.60 |

3.70 |

5 |

10 |

* 1/4 |

1 |

1/8 |

3-6 |

3.80 |

3.30 |

6.60 |

12 |

5/16 |

1 3/8 |

4-6 |

5.10 |

4.50 |

10.00 |

8 |

16 |

* 3/8 |

1 11/16 |

5-0 |

7.30 |

6.40 |

15.00 |

8 |

16 |

7/16 |

2 |

5-9 |

11.00 |

10.00 |

23.00 |

9 |

18 |

1/2 |

2 1/4 |

6-5 |

15.00 |

13.00 |

30.00 |

9 |

18 |

9/16 |

2 1/2 |

8-0 |

19.00 |

16.00 |

38.00 |

12 |

24 |

5/8 |

2 13/16 |

9-4 |

23.00 |

20.00 |

46.00 |

14 |

28 |

3/4 |

3 3/8 |

- |

33.00 |

29.00 |

66.00 |

- |

- |

7/8 |

4 |

- |

45.00 |

39.00 |

89.00 |

- |

- |

1 |

4 1/2 |

- |

58.00 |

51.00 |

116.00 |

- |

- |

1 1/8 |

5 |

- |

73.00 |

64.00 |

146.00 |

- |

- |

1 1/4 |

5 5/8 |

- |

89.00 |

78.00 |

179.00 |

- |

- |

1 3/8 |

6 3/18 |

- |

108.00 |

94.00 |

215.00 |

- |

- |

1 1/2 |

6 3/4 |

- |

128.00 |

112.00 |

255.00 |

- |

- |

1 5/8 |

7 5/16 |

- |

148.00 |

129.00 |

296.00 |

- |

- |

1 3/4 |

7 7/8 |

- |

171.00 |

150.00 |

343.00 |

- |

- |

1 7/8 |

8 7/16 |

- |

195.00 |

171.00 |

390.00 |

- |

- |

2 |

9 |

- |

222.00 |

194.00 |

444.00 |

- |

- |

Larger sizes available.

* Standard galvanized 7 x 19 through 3/8″ component ropes.

** Rated capacities of basket hitches are based on minimum diameter of curvature at the point of load

contact of 20 times the rope diameter

*** Rated capacities of choker hitches apply when the angle of choke is greater than 135°.

PERTINENT DIMENSIONS FOR END FITTINGS

Sling Size Inches |

Loop Inside |

Slip-Thru Thimble Inside |

Alloy Hook |

Shackle with Thimble |

Half Thimble |

|||

|---|---|---|---|---|---|---|---|---|

Width In. |

Length In. |

Width In. |

Length In. |

Size Tons |

Size In. |

Width In. |

Length In. |

|

3/32 |

1 1/2 |

3 |

2 1/8 |

4 1/8 |

1 |

1/4 |

- |

- |

1/8 |

2 |

4 |

2 1/8 |

4 1/8 |

1 1/2 |

3/8 |

2 |

4 |

3/16 |

3 |

6 |

2 3/8 |

4 3/8 |

3 |

1/2 |

2 1/4 |

6 |

1/4 |

4 |

8 |

3 3/8 |

6 5/8 |

4 1/2 |

5/8 |

3 1/4 |

8 |

5/16 |

5 |

10 |

3 3/4 |

7 1/8 |

7 |

3/4 |

4 1/2 |

10 |

3/8 |

8 |

12 |

3 3/4 |

7 1/8 |

11 |

7/8 |

4 5/8 |

12 |

7/16 |

7 |

14 |

4 3/8 |

8 3/8 |

15 |

1 1/8 |

5 1/2 |

14 |

1/2 |

8 |

16 |

5 |

9 1/2 |

15 |

1 1/4 |

6 |

16 |

9/18 |

9 |

18 |

5 |

9 1/2 |

22 |

1 1/2 |

6 1/2 |

18 |

5/8 |

10 |

20 |

6 3/4 |

11 3/4 |

30 |

1 3/4 |

7 |

20 |

3/4 |

12 |

24 |

8 |

14 1/2 |

37 |

2 |

8 |

24 |

7/8 |

14 |

28 |

8 3/8 |

17 5/8 |

45 |

2 |

- |

- |

1 |

16 |

32 |

8 3/8 |

17 5/8 |

60 |

2 1/8 |

- |

- |

Braided Slings Type 19

Helically laid with one continuous wire rope running through both eyes and the body

Flexibility and handing ease for rigging large lifts is achieved in these 9-part slings by laying a single wire rope continuously through both eyes and the sling body so that nine parts of rope form the body. This proven design provides internal adjustment to distribute the load evenly among all nine parts of the body when a sling is in tension. In addition, the construction makes it possible to visually inspect all internal parts of the sling before and after each lift — important when a sling is to be used many times. Only two splices occur in the entire sling, where the two rope ends are spliced at the eyes.

A 9-part sling construction exhibits constructional stretch of approximately 1 1/2% on the first loading, and a lesser amount thereafter. For this reason, lifts using two or more legs should always be made with legs which have been subjected to the same past usage when such stretch may affect the lift.

9-PART BRAID, HAND TUCKED SPLICE, IWRC

Vertical, Choker, or Vertical Basket

RATED CAPACITY IN TONS OF 2,000 lbs.

RATED CAPACITIES SHOWN APPLY ONLY TO 6X19 AND 6X36 CLASSIFICATION WIRE ROPE

ROPE DIAMETER (INCHES) |

VERTICAL |

CHOKER |

VERTICAL BASKET |

|||

|---|---|---|---|---|---|---|

IPS |

EIPS |

IPS |

EIPS |

IPS |

EIPS |

|

3/32* |

0.63 |

- |

0.55 |

- |

1.3 |

- |

1/8* |

1.3 |

- |

1.1 |

- |

2.5 |

- |

3/16 |

2.1 |

2.4 |

1.8 |

2.1 |

4.2 |

4.8 |

1/4 |

3.7 |

4.3 |

3.2 |

3.7 |

7.4 |

8.6 |

5/16 |

5.8 |

6.6 |

5.0 |

5.8 |

12 |

13 |

3/8 |

8.3 |

9.5 |

7.2 |

8.3 |

17 |

19 |

7/16 |

11 |

13 |

9.8 |

11 |

22 |

26 |

1/2 |

14 |

17 |

13 |

15 |

29 |

34 |

9/16 |

18 |

21 |

16 |

19 |

37 |

42 |

5/8 |

23 |

26 |

20 |

23 |

45 |

52 |

3/4 |

32 |

37 |

28 |

32 |

65 |

74 |

7/8 |

44 |

50 |

38 |

44 |

87 |

100 |

1 |

57 |

65 |

50 |

57 |

113 |

130 |

1 1/8 |

71 |

82 |

62 |

72 |

142 |

164 |

1 1/4 |

87 |

101 |

77 |

88 |

175 |

201 |

1 3/8 |

105 |

121 |

92 |

106 |

210 |

242 |

1 1/2 |

125 |

144 |

109 |

126 |

249 |

287 |

1 5/8 |

145 |

166 |

127 |

146 |

290 |

333 |

1 3/4 |

168 |

193 |

147 |

169 |

335 |

386 |

1 7/8 |

192 |

219 |

168 |

192 |

383 |

438 |

2 |

217 |

249 |

190 |

218 |

433 |

499 |

* NOTE: 3/12 & 1/8 utilize Galvanized Small Cord minimum breaking force.

|

||||||

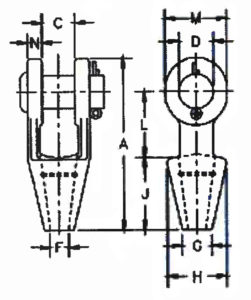

- Open Spelter Sockets

- Closed Spelter Sockets

- Swage Sockets

Open Spelter Sockets

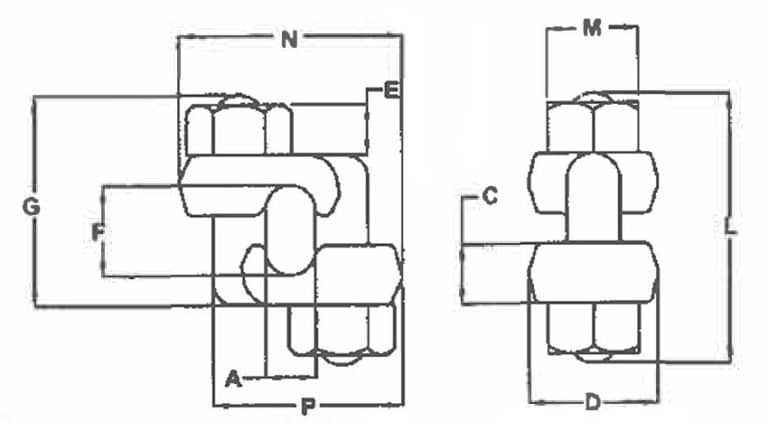

Sockets are cast alloy steel. Meets or exceeds Federal Specifications RR-S-550 latest revision strength &

dimensionally. Drawing illustrates on internal groove used on 1/4″ through 3/4″. 7/8″ through 1 1/2″ have two

grooves. 1 5/8″ and larger have three grooves.

Spelter socket terminations have an efficiency rating of 100%, based on the catalog strength of wire

rope. Ratings are based on recommended use with 6 x 7, 6 x 19, or 6 x 37, IPS or XIP (EIP), XXIP (EEIP), RRL, FC, or IWRC wire rope.

STANDARD OPEN WIRE ROPE SPELTER SOCKETS

|

Rope Dia. (in.) |

Structural Strand Dia. (in.) |

Weight Each (lbs.) |

Dimensions (in.) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

A |

C |

D |

F |

G |

H |

J |

L |

M |

N |

|||

|

1/4 |

- |

1.10 |

4.56 |

.75 |

.69 |

.38 |

.69 |

1.56 |

2.25 |

1.56 |

1.31 |

.36 |

|

5/16 - 3/8 |

- |

1.30 |

4.84 |

.81 |

.81 |

.50 |

.81 |

1.69 |

2.25 |

1.75 |

1.50 |

.44 |

|

7/18 - 1/2 |

- |

2.25 |

5.56 |

1.00 |

1.00 |

.56 |

.94 |

1.88 |

2.50 |

2.00 |

1.88 |

.50 |

|

9/16 - 1/8 |

1/2 |

3.60 |

6.75 |

1.25 |

1.19 |

.69 |

1.13 |

2.25 |

3.00 |

2.50 |

2.25 |

56 |

|

3/4 |

9/16 - 5/8 |

5.83 |

7.94 |

1.50 |

1.38 |

.81 |

1.25 |

2.62 |

3.50 |

3.00 |

2.62 |

.62 |

|

7/8 |

11/16 - 3/4 |

9.65 |

9.25 |

1.75 |

1.63 |

.94 |

1.50 |

3.25 |

4.00 |

3.50 |

3.13 |

.80 |

|

1 |

13/16 - 7/8 |

15.5 |

10.56 |

2.00 |

2.00 |

1.13 |

1.75 |

3.75 |

4.50 |

4.00 |

3.75 |

.88 |

|

1 1/8 |

15/16 - 1 |

21.5 |

11.81 |

2.25 |

2.25 |

1.25 |

2.00 |

4.12 |

5.00 |

4.62 |

4.12 |

1.00 |

|

1 1/4 - 1 3/8 |

1 1/16- 1 1/8 |

31.00 |

13.19 |

2.50 |

2.50 |

1.50 |

2.25 |

4.75 |

5.50 |

5.00 |

4.75 |

1.13 |

|

1 1/2 |

1 3/16 - 1 1/4 |

47.25 |

15.12 |

3.00 |

2.75 |

1.63 |

2.75 |

5.25 |

6.00 |

6.00 |

5.38 |

1.19 |

|

* 1 5/8 |

1 5/16 - 1 3/8 |

55.00 |

16.25 |

3.00 |

3.00 |

1.75 |

3.00 |

5.50 |

6.50 |

6.50 |

5.75 |

1.31 |

|

*1 3/4 - 1 7/8 |

1 7/16 - 1 5/8 |

82.00 |

18.25 |

3.50 |

3.50 |

2.00 |

3.13 |

6.38 |

7.50 |

7.00 |

6.50 |

1.56 |

|

* 2 - 2 1/8 |

1 11/16 - 1 3/4 |

129.00 |

21.50 |

4.00 |

3.75 |

2.25 |

3.75 |

7.38 |

8.50 |

9.00 |

7.00 |

1.81 |

|

*2 1/4 - 2 3/8 |

1 13/16 - 1 7/8 |

167.00 |

23.50 |

4.50 |

4.25 |

2.50 |

4.00 |

8.25 |

9.00 |

10.00 |

7.75 |

2.13 |

|

* 2 1/2 - 2 5/8 |

1 15/16 - 2 1/8 |

252.00 |

25.50 |

5.00 |

4.75 |

2.88 |

4.50 |

9.25 |

9.75 |

10.75 |

8.50 |

2.38 |

|

* 2 3/4 - 2 7/8 |

2 3/16 - 2 7/16 |

315.00 |

27.25 |

5.25 |

5.00 |

3.12 |

4.88 |

10.50 |

11.00 |

11.00 |

9.00 |

2.88 |

|

* 3 - 3 1/8 |

2 1/2 - 2 5/8 |

380.00 |

29.00 |

5.75 |

5.25 |

3.38 |

5.25 |

11.12 |

12.00 |

11.25 |

9.50 |

3.00 |

|

*3 1/4 - 3 3/8 |

2 3/4 - 2 7/8 |

434.00 |

30.88 |

6.25 |

5.50 |

3.62 |

5.75 |

11.88 |

13.00 |

11.75 |

10.00 |

3.12 |

|

* 3 1/2 - 3 5/8 |

3 - 3 1/8 |

583.00 |

33.25 |

6.75 |

6.00 |

3.88 |

6.50 |

12.38 |

14.00 |

12.50 |

10.75 |

3.25 |

|

* 3 3/4 - 4 |

- |

783.00 |

36.25 |

7.50 |

7.00 |

4.25 |

7.25 |

13.62 |

15.00 |

13.50 |

12.50 |

3.50 |

|

* Cast Alloy Steel |

||||||||||||

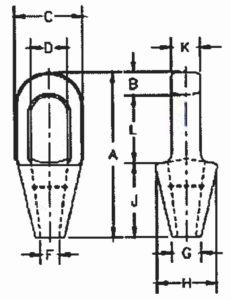

Closed Spelter Sockets

STANDARD OPEN WIRE ROPE SPELTER SOCKETS

|

Rope Dia. (in.) |

Structural Strand Dia. (in.) |

Weight Each (lbs.) |

Dimensions (in.) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

A |

B |

C |

D * |

F |

G |

H |

J |

K |

L |

|||

|

1/4 |

- |

.50 |

4.50 |

.50 |

1.50 |

.88 |

.38 |

.69 |

1.56 |

2.25 |

.50 |

1.75 |

|

5/16 - 3/8 |

- |

.75 |

4.88 |

.62 |

1.69 |

.97 |

.50 |

.81 |

1.69 |

2.25 |

.69 |

2.00 |

|

7/16 - 1/2 |

- |

1.50 |

5.44 |

.69 |

2.00 |

1.16 |

.56 |

.94 |

1.88 |

2.50 |

.88 |

2.25 |

|

9/16 - 5/8 |

1/2 |

2.50 |

6.31 |

.81 |

2.63 |

1.41 |

.69 |

1.12 |

2.38 |

3.00 |

1.00 |

2.50 |

|

3/4 |

9/16 - 5/8 |

4.25 |

7.56 |

1.06 |

3.00 |

1.66 |

.81 |

1.25 |

2.75 |

3.56 |

1.25 |

3.00 |

|

7/8 |

11/16 - 3/4 |

7.25 |

8.75 |

1.25 |

3.63 |

1.88 |

.94 |

1.50 |

3.25 |

4.00 |

1.50 |

3.50 |

|

1 |

13/16 - 7/8 |

10.50 |

9.88 |

1.38 |

4.13 |

2.30 |

1.13 |

1.75 |

3.75 |

4.44 |

1.75 |

4.00 |

|

1 1/8 |

15/16 - 1 |

14.25 |

11.00 |

1.50 |

4.50 |

2.56 |

1.25 |

2.00 |

4.13 |

5.00 |

2.00 |

4.50 |

|

1 1/4 - 1 3/8 |

1 1/16 - 1 1/8 |

19.75 |

12.12 |

1.63 |

5.30 |

2.81 |

1.50 |

2.25 |

4.75 |

5.50 |

2.25 |

5.00 |

|

1 1/2 |

1 3/16 - 1 1/4 |

29.20 |

13.94 |

1.94 |

5.33 |

3.19 |

1.63 |

2.75 |

5.25 |

8.00 |

2.50 |

6.00 |

|

** 1 5/8 |

1 5/16 - 1 3/8 |

36.00 |

15.13 |

2.13 |

5.75 |

3.25 |

1.75 |

3.00 |

5.50 |

6.50 |

2.75 |

6.50 |

|

** 1 3/4 - 1 7/8 |

1 7/16 - 1 5/8 |

57.25 |

17.25 |

2.19 |

6.75 |

3.75 |

2.00 |

3.13 |

6.38 |

7.50 |

3.00 |

7.56 |

|

** 2 - 2 1/8 |

1 11/16 - 1 3/4 |

79.00 |

19.50 |

2.44 |

7.63 |

4.38 |

2.25 |

3.75 |

7.38 |

8.50 |

3.25 |

8.56 |

|

** 2 1/4 - 2 3/8 |

1 13/16 - 1 7/8 |

105.00 |

21.13 |

2.63 |

8.50 |

5.00 |

2.50 |

4.00 |

8.25 |

9.00 |

3.63 |

9.50 |

|

** 2 1/2 - 2 5/8 |

1 15/18 - 2 1/8 |

140.00 |

23.50 |

3.12 |

9.50 |

5.50 |

2.88 |

4.50 |

9.25 |

9.75 |

4.00 |

10.62 |

|

** 2 3/4 - 2 7/8 |

2 3/16 - 2 7/16 |

220.00 |

25.38 |

3.12 |

10.75 |

6.25 |

3.12 |

4.88 |

10.19 |

11.00 |

4.88 |

11.25 |

|

** 3 - 3 1/8 |

2 1/2 - 2 5/8 |

276.00 |

27.00 |

3.25 |

11.50 |

6.75 |

3.38 |

5.25 |

11.50 |

12.00 |

5.25 |

11.75 |

|

** 3 1/4 - 3 3/8 |

2 3/4 - 2 7/8 |

313.00 |

29.25 |

4.00 |

12.25 |

7.25 |

3.62 |

5.75 |

12.25 |

13.00 |

5.75 |

12.25 |

|

** 3 1/2 - 3 5/8 |

3 - 3 1/8 |

400.00 |

31.00 |

4.00 |

13.00 |

7.75 |

3.88 |

6.50 |

13.00 |

14.00 |

6.25 |

13.00 |

|

** 3 3/4 - 4 |

- |

542.00 |

33.25 |

4.25 |

14.25 |

8.50 |

4.25 |

7.25 |

14.25 |

15.00 |

7.00 |

14.00 |

|

* Diameter of pin must not exceed pin used on companion 416 socket. Reference adjacent page "D"

dimension. |

||||||||||||

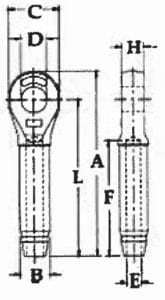

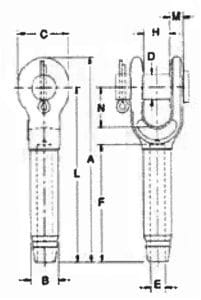

Swage Sockets

Swage sockets are recommend for use on 6 x 19 or 6 x 36 IWRC regular lay ropes. They are NOT recommended for use on fiber core or lang lay ropes. Sockets properly applied have an efficiency rating of 100% based on the catalog breaking strength of wire rope. In accordance with ANSI 830.9, all slings terminated with swage sockets shall be proof loaded. Maximum Proof Load shall not exceed 50% of XXIP rope catalog breaking strength.

OPEN SWAGE SOCKETS

|

S-501 Open Socket Specifications |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Rope Size (in.) |

Weight Each (lbs) |

Before Swage Dimensions |

Max. After Swage Dim. (in.) |

|||||||||

|

A |

B |

C |

D |

E |

F |

H |

L |

M |

N |

|||

|

1/4 |

.52 |

4.78 |

.50 |

1.38 |

.69 |

.27 |

2.19 |

.69 |

4.00 |

.38 |

1.47 |

.46 |

|

5/16 |

1.12 |

6.30 |

.78 |

1.62 |

.81 |

.34 |

3.25 |

.80 |

5.34 |

.48 |

1.67 |

.71 |

|

3/8 |

1.30 |

6.30 |

.78 |

1.62 |

.81 |

.41 |

3.25 |

.80 |

5.34 |

.48 |

1.67 |

.71 |

|

7/16 |

2.08 |

7.82 |

1.01 |

2.00 |

1.00 |

.49 |

4.31 |

1.00 |

6.69 |

.56 |

1.96 |

.91 |

|

1/2 |

2.08 |

7.82 |

1.01 |

2.00 |

1.00 |

.55 |

4.31 |

1.00 |

6.69 |

.56 |

1.96 |

.91 |

|

9/16 |

4.67 |

9.54 |

1.27 |

2.38 |

1.19 |

.61 |

5.38 |

1.25 |

8.13 |

.68 |

2.21 |

1.16 |

|

5/8 |

4.51 |

9.54 |

1.27 |

2.38 |

1.19 |

.68 |

5.38 |

1.25 |

8.13 |

.68 |

2.21 |

1.16 |

|

3/4 |

7.97 |

11.61 |

1.56 |

2.75 |

1.38 |

.80 |

6.44 |

1.50 |

10.00 |

.78 |

2.69 |

1.42 |

|

7/8 |

11.52 |

13.37 |

1.72 |

3.13 |

1.63 |

.94 |

7.50 |

1.75 |

11.63 |

.94 |

3.20 |

1.55 |

|

1 |

17.80 |

15.47 |

2.00 |

3.69 |

2.00 |

1.07 |

8.63 |

2.00 |

13.38 |

1.07 |

3.68 |

1.80 |

|

1 1/8 |

25.25 |

17.35 |

2.25 |

4.06 |

2.25 |

1.19 |

9.75 |

2.25 |

15.00 |

1.19 |

4.18 |

2.05 |

|